Current Instrumentation

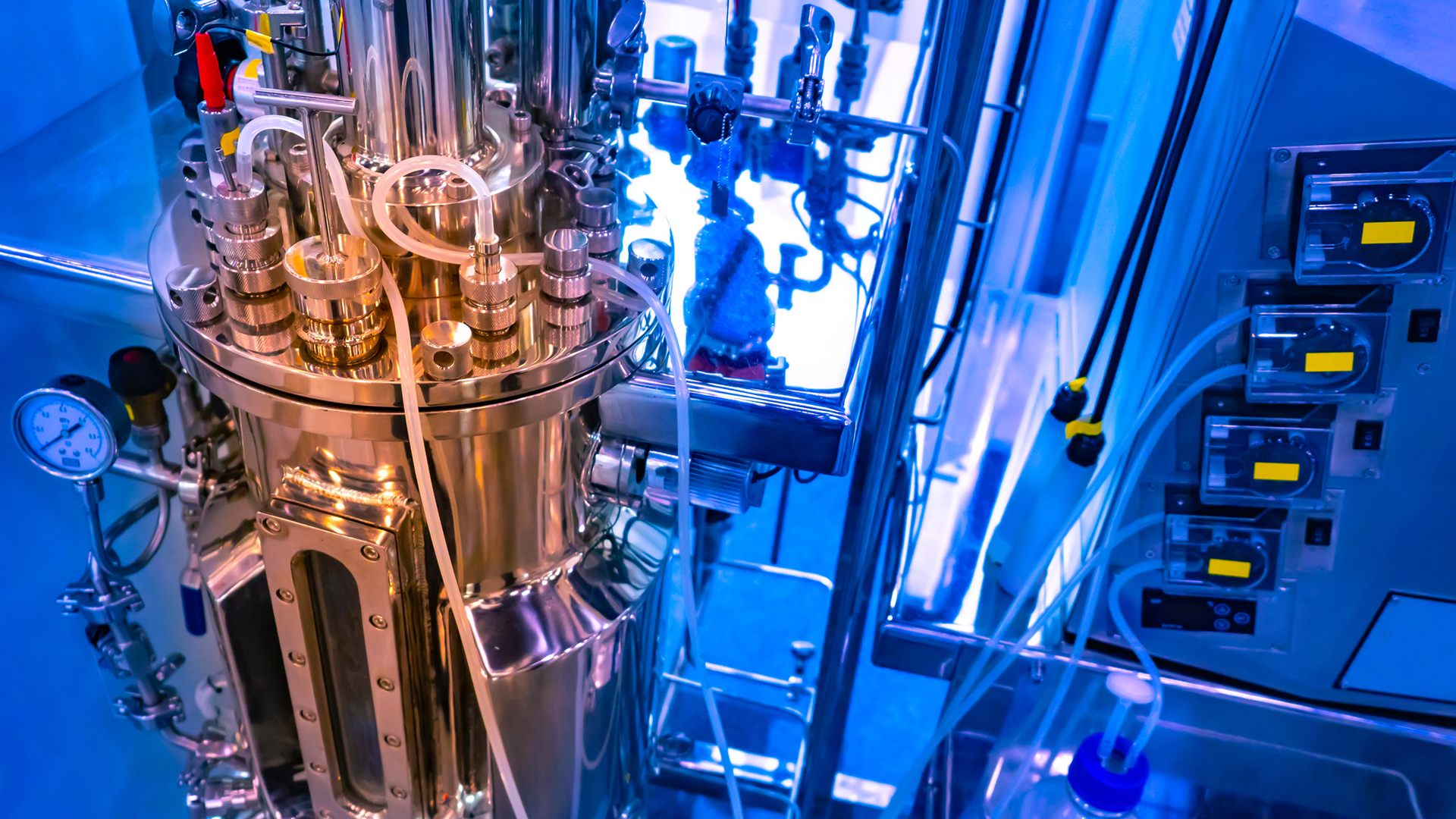

The fermentation platform is distinguished by its combination of advanced fermentation, analytical and purification facilities as well as automated cultivation equipment. It has a fermentor capacity which is unique within the research field of fermentation and is located in newly renovated laboratories.

Our current instrumentation include:

Fermentation laboratories

Our facilities consist of multiple fermenters of varying size:

- 24 1 liter fermentors

- 6 5 liter fermentors

- 2 10 liter fermentors with advanced online analysis equipment (fluorescence and NIR detectos, glucose sensors, ect.) for studies on online fermentation monitoring

- 6 0.5 liter fermentors for labeled substrate experiments (e.g. C13 metabolic flux analysis)

All fermentors can be operated in batch, fed-batch, or continuous mode with the possibility for overflow and weight-based control. The facilities are used for research projects at bachelor, master and PhD level and support teaching activities in fermentation technology.

All fermentors are from Sartorius and these new bioreactor systems offer flexibility in terms of both fermentation type and size of working volume. The setups are all equipped with the same user friendly software which alloes trained personnel to Work with all the systems. Futhermore, the applied software has numerous applications suited for chemostat and fed-batch setups. Specifically the possibility for running weight based chemostat cultivations is an attractive feature when working with filamentous organisms. Finally, a desirable attribute of the systems is that the feed pump can by coupled to a feed weight, enabling a very precise dosing profile which is essential for running both chemostat and fed-batch cultures.

Gas analysis

A state-of-the-art mass spectrometer off gas analysis detector is coupled to the equipment in the fermentation laboratories. The instrument provides high precision gas quenatification and in addition can also be applied for identification of volatile compounds inthe off-gas.

Each fermentation room is adjacent to an analysis room equipped with the basic sample preparation instruments (spectrophotometers, centrifuges, vacuum pumps, microwave ovens, etc.).

The support facilities include autoclaves, several -80 °C freezers for strain storage, freezers and fridges for sample and media storage, four sterile rooms with laminar flow benches, two incubation rooms with ovens and shaking tables, two weighing rooms for medium preparation and biomass weight analyses, and dish washing room.

Mammalian cell laboratory

A fully equipped class 2 Facility for cultivation of mammalian cells is located in building 223, including 4 Das Gip 1 L-bioreactor systems.

The Fermentation Platfrom has a close collaboration with the extensive analysis core DTU Metabolomics Core, which is located in building 221.

Contact

Tina Johansen Lab Manager Department of Biotechnology and Biomedicine Phone: +45 45252683 Mobile: 2029 6589 tj@bio.dtu.dk